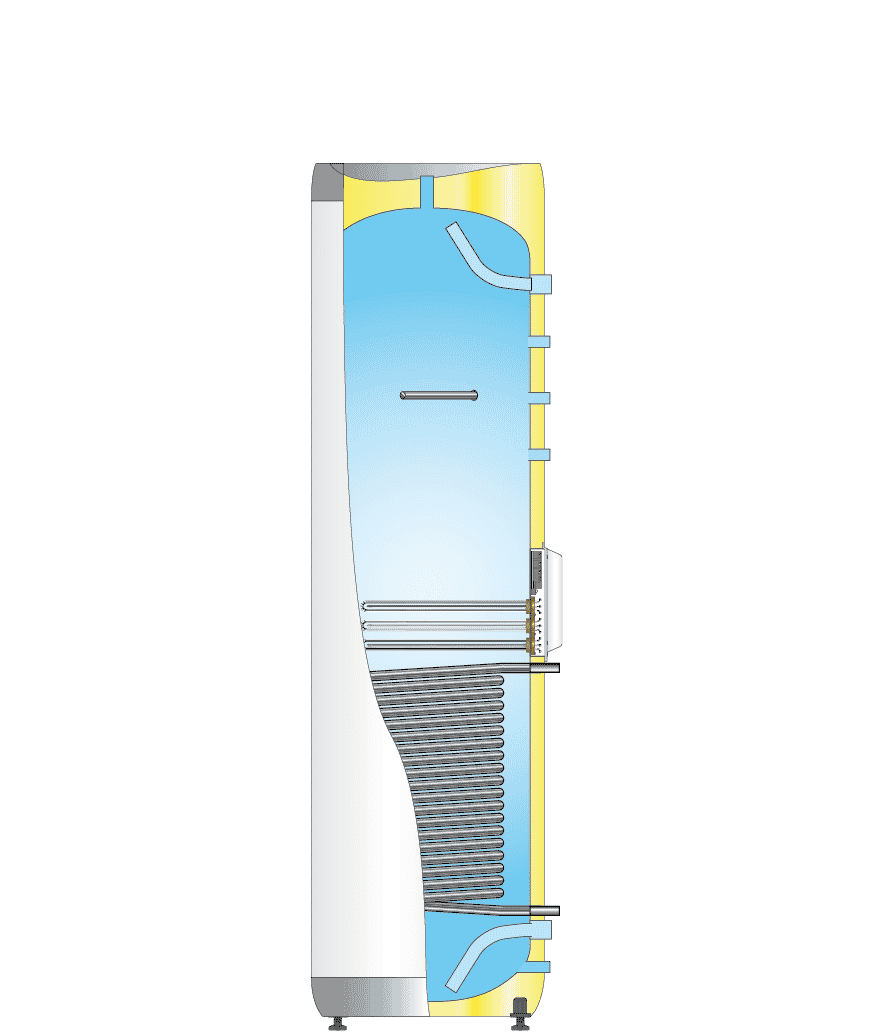

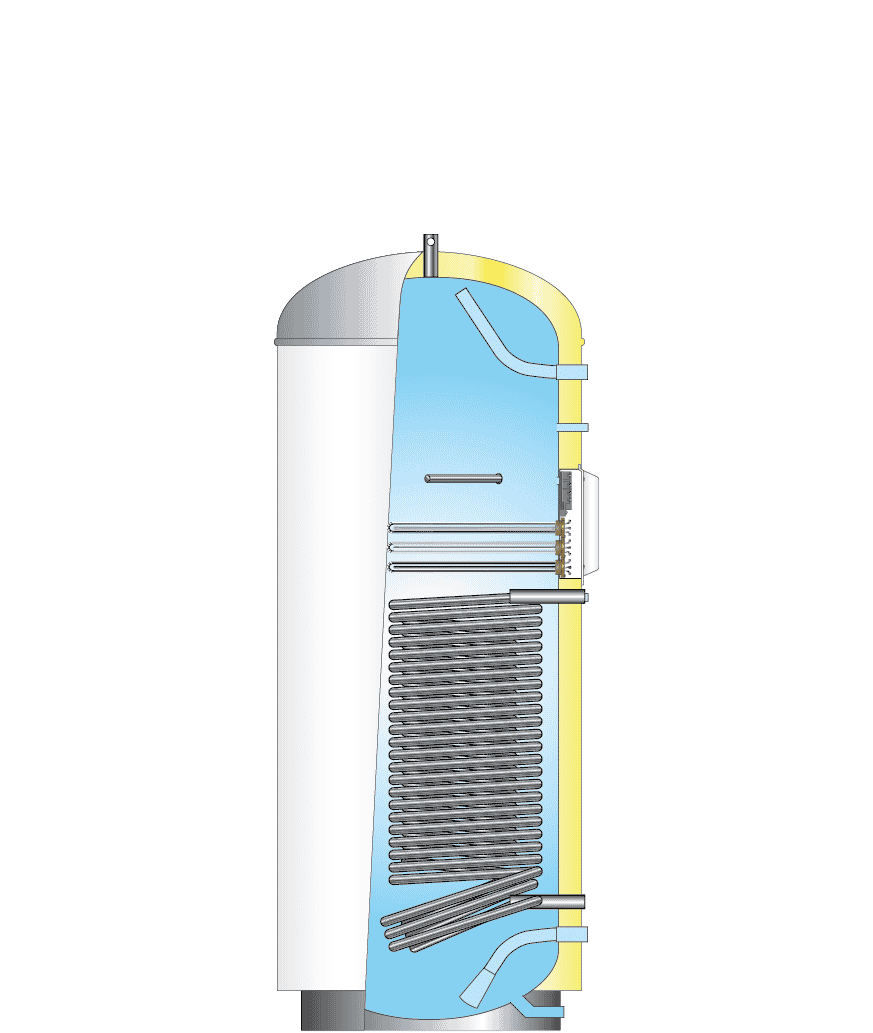

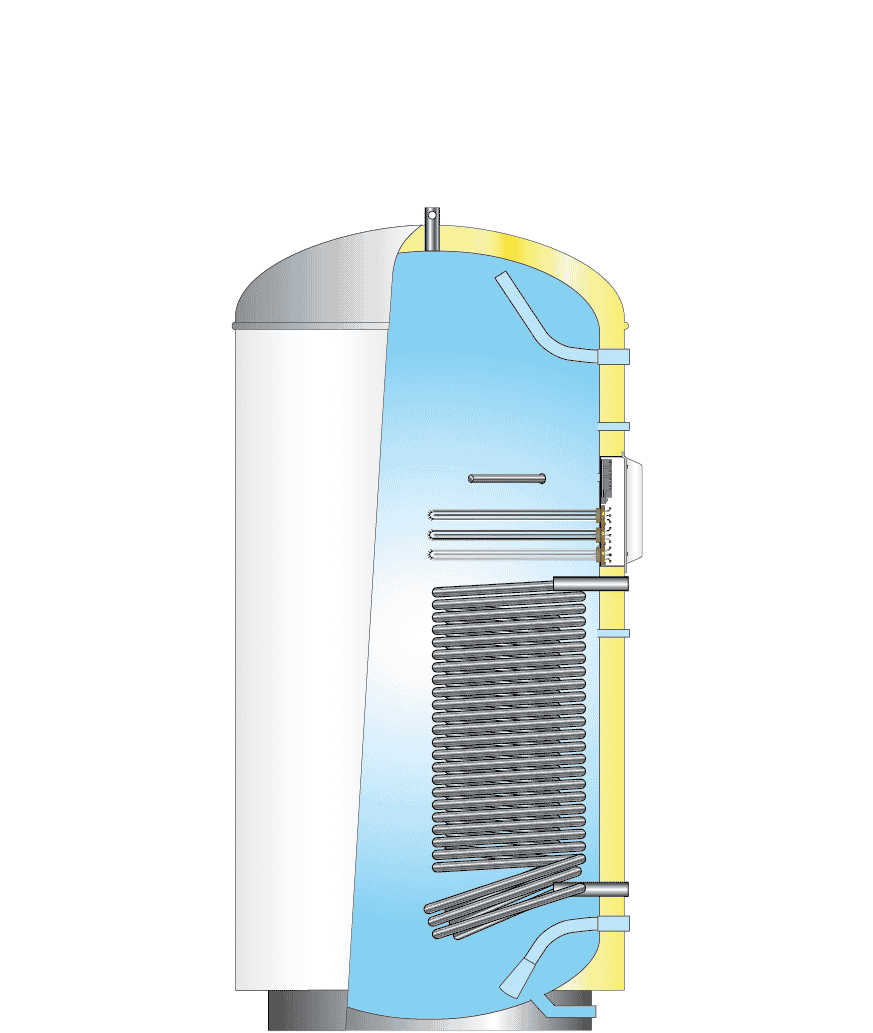

Custom designed for heat pumps up to 40 kW

MAXI GEOCOIL — MGC — is custom-made for maximum hot water production from heat

pumps up to 40 kW (400 L = 25 kW / 600 / 1000 L = 40 kW), with the extremely large tube

heat exchanger (400L = 3.1m² / 600L = 4.6m²/ 1 000L = 7.0m²). The units are also suitable

for solar collectors up to 40m². MAXI GEOCOIL features electric heating elements as booster raising the temperature above the heat exchanger to further increase capacity. The booster heaters also provides maximum safety vs. bacterial growth or if there are any operational problems with the energy source.The electric immersion heaters comes with optional power 2.5–15 kW, 230–400 V + N3-phase, and is thermostat controlled 50–75°C.

Installation kits for cold water inlet with shutoff valve, hot water outlet with mixing valve and piping for connecting multiple units has been custom-made to fit directly on the MAXI series.

The commercial cylinders in the MAXI series have shown class-leading operational durability for commercial hot water systems through the last 50 years.

WHY CHOOSE MAXI GEOCOIL?

• Highly efficient DHW production from heat pumps up to 40 kW

• Extreme operational safety with electric heater as booster / back-up

• 10 bar design pressure and class-leading corrosion resistance